About

A Leader In Precision Parts Manufacturing For More Than 70 Years.

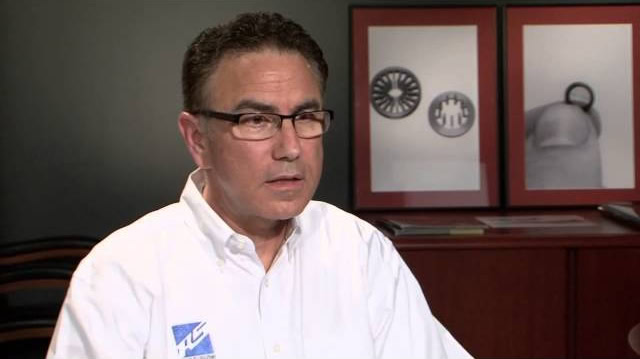

CEO Bob Savitzky explains how a robust manufacturing process helps

eliminate hidden costs and delivery delays.

Launched in 1948 as a modest tool and die shop, RS Precision has evolved into a leading manufacturer of highly complex parts utilized by our nation’s most renowned aerospace, defense, and medical suppliers. What sets us apart? Our expertise in a diverse range of machining capabilities. This allows RS Precision to develop the most advantageous manufacturing solution, one that produces the best performing and most consistent complex part at a competitive cost. What’s more, we offer our customers the convenience and accountability of a one-stop source. So there’s no unnecessary delays.

Quality.

Built Into Everything We Do.

RS Precision is committed to producing high-quality, mission-critical complex parts that meet AS 9100 – ISO 9001 standards. We continually improve and update our processes and quality-centric infrastructure through best-in-class, rigorous procedures based on lean manufacturing and Six Sigma practices.

Management Team

Robert Savitzky,

Chief Executive Officer

After starting his career as a Manufacturing Engineer at Hewlett Packard, Bob took the lead at RS Precision when its founder (and his father), Abe Savitzky, retired more than 35 years ago. Today, Bob has grown the company from a tool and die shop into one of the nation’s most recognized multi-process manufacturers of complex, mission-critical parts. His collaborative “beyond the blueprint” methodology has resulted in parts that not only better perform, but offer more bottom-line value to customers. Bob holds a Bachelor of Science degree in Mechanical Engineering from New York’s Cornell University.