With an eye toward market trends, over the past three years RS Precision has made significant investments to grow our business, first and foremost expanding our facility to 18,000 square feet in order to house a growing line-up of CNC Machining Centers. These machines have enabled us to meet increasing demands from aerospace and defense equipment manufacturers.

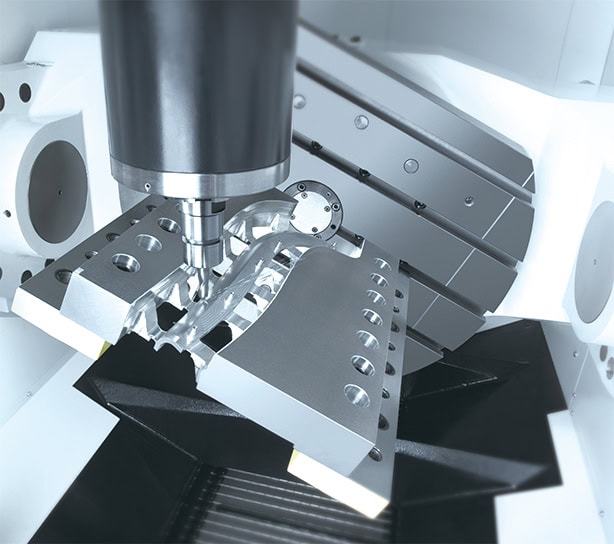

While Vertical Machining Centers have been the mainstay of our production capability, we have recently made strategic investments in Multi-Axis and Horizontal machining centers. Multi-Axis machines perform both milling and turning in the same machine and allow complete, complex parts to be produced in one operation. Horizontal machining provides higher productivity for larger and four-axis parts.

Here are some of our investments, including their specifications that make all the difference when producing complex parts that demand precision, consistency, and, of course, quality:

Multi-Axis machines. Offer advanced capabilities in turning and milling:

- Mori Seiki NT-1000-ZSM Multi-Axis CNC Machining Center, 12,000 5-Axis Milling Spindle with 76 Position Tool Changer, 6,000 RPM x 2.5” Bar Capacity Main and Sub-Spindles, Automatic Bar Feeder

- Mazak Integrex i150 5-Axis CNC Machining Center, 20,000 rpm, 72 tools, 5,000 RPM Main Spindle x 2.5” Bar Capacity, Automatic Bar Feeder.

CNC milling machines. Increase our ability to machine larger components, as well as difficult-to-machine hardened metals:

- Mazak HMC-4000 II Horizontal Machining Center, Dual Pallet (22” x 24” travel, 18,000 RPM, 80 tools)

- Mazak VCN 570C Vertical Machining Center (51” x 22” travel, 15,000 RPM, 30 tools)

- Mazak VCN 430B Vertical Machining Center (43” x 17” travel, 15,000 RPM, 30 tools)

I’m really proud to say that our production of aerospace and defense components has risen 48% within the past few years, and that’s essentially the result of this equipment and, of course, our skilled and experienced operators. Combine the two with RS Precision’s steadfast compliance to AS9100 and ISO 9001 standards, and the result is on-time finished parts with optimum quality, job after job.

If you’re interested, I’d be more than happy to arrange a tour of our facility so you can experience first-hand our capabilities—not to mention our capacity. Feel free to contact me at mpentecoste@rsprecision.com to schedule a private tour.